Platform Grating

The main purpose of Platform Grating, which is generally used as a carrier building element, is to prevent oil, dust and liquids from accumulating on the floors in the workplace, eliminating situations that threaten the safety of employees.

Platform Grating models are high carrying capacity products that also allow light, air, sound and liquid passage, allowing for use for both safety and partitioning purposes. It is widely used in many industries with its durable, lightweight and safety-enhancing properties.

Easily Carry Heavy Loads with Platform Grating

The Honeycomb grating is a carrier building element designed to carry heavy loads with minimal weight. On the floor of the working area, in addition to preventing the accumulation of substances such as dust, liquids and oil, it is the most economical way to optimize pedestrian and vehicle movement. It provides ventilation, light transition and field of view with a wide percentage of open space. In this respect, it increases the occupational safety of employees. It is used in many fields and sectors in light, durable and security-enhancing aspects. Honeycomb grating is designed and manufactured according to different load requirements for different applications, taking into account customer requests and expectations.

What are the General Features of Platform Grills?

Honeycomb grill is a durable and long-lasting product that provides visibility, light, ventilation, dust, liquid and sound passage with its open space capability, where pedestrian and vehicle movement can be optimized with high carrying capacity. It is designed and manufactured to meet different load requirements in many fields and industries. Carrying capacity of the material differs as to the material’s thickness, height and eye openness between carrier metal sheets. When the products in the sector are examined, the most preferred eye openings according to DIN standards are seen that it has dimensions of 33×33 mm on half-pass and full passing gratings and 34×38 mm on gratings with twisted iron.

This product is produced in master hands with accurate and good quality material which are extremely resistant to adverse external factors of corrosion, rusting, etc. and have a long lifespan. Honeycomb grating is coated with hot dip galvanized In TS ISO EN 1461 standards, and thus provides resistance to corrosion. Galvanized grids are zinc coated, durable and metal grids with very high corrosion resistance. The durability and service life of gratings exposed to corrosive materials or elements, which are in continuous use in industrial, domestic and commercial applications, are extended with this method.

Other features of the platform grating, the two most well-known features of which are heavy load carrying capacity and corrosion-resistant, have been available for many years, can be listed as follows:

- It is resistant to concussions and impacts.

- The installation process is easy and practical.

- It can be specially painted according to customer requests and expectations.

- Thanks to the immersion galvanized coating, the galvanized grating can be used for many years.

- With coating types, the non-slip feature can be increased.

- It can be designed and manufactured in different ways for light or heavy load applications.

- It provides effective solutions for both commercial and industrial applications.

- Electro-galvanized and hot dip galvanized can be applied.

What are the Platform Grating Usage Areas?

Honeycomb grating provides many advantages such as ease of use, heavy load carrying capacity, longevity. It has a wide range of uses with these advantages. The common uses of this product, which is used in many commercial, industrial and domestic sectors, can be listed as follows;

- It is widely used in;

- In power plants, cement factories, treatment plants,

- In concrete plants, refineries and dams,

- In harbors and ships,

- In social facilities and garden railings,

- Machine walking paths and fire stairs,

In canals, rolling mills, tower poles, - In the ventilation covers,

- In suspended ceilings, chimneys, roof cavities, elevator ducts.

System Platform Platform Grating Types

High quality honeycomb grating systems that can be used for many years and produced by expert hands are produced in 4 different models by System Platform : square twist grating, half-pass grating, full passing grating and special production grating. All grating models produced are customized according to customer requests and needs with system platform quality and assurance and delivered just in time. Now, let’s examine in detail these types of honeycomb gratings that we produce.

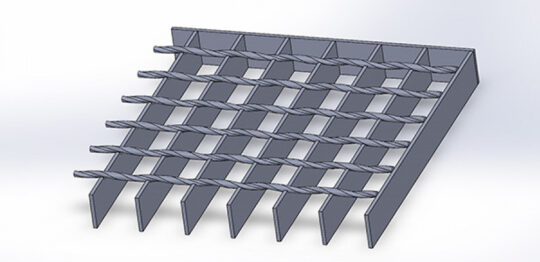

1- Square Twist Grating:

Square twisted gratings are one of the most well-known varieties of honeycomb gratings and are widely used. Square twist gratings can also be added to the non-scroll feature on demand. Thanks to the notches on the metal sheets, the non-scrolling is increased. This product can be ordered in the form of standard panels. In addition, in line with the wishes and expectations of our customers, production can be made according to the projects to be implemented and operations such as special add-ons are carried out carefully by our expert team.

Depending on the weight of the load to be transported, the thickness and height of the carrier metal sheets varies. The product is manufactured and hot dip galvanized is applied to increase its durability, service life and resistance to corrosion. It is produced in high quality, painted or uncoated, according to the needs of the project. This product is mostly preferred in refineries, power plants, concrete plants, cement factories, treatment plants and industrial projects.

Square twist gratings designed by System Platform in accordance with high quality standards:

- Square Twist Standard Gratings,

- Square Twist Standard Stair Step,

- Square Twist Notched Stair Step,

- Square Twist NotchEd Grating.

It is produced in 4 different types.

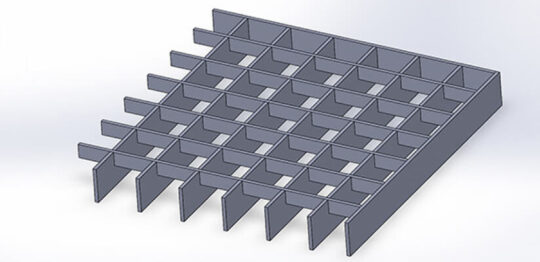

2- Half Pass Grating:

In this type of grid, dispenser and carrier elements are produced from metal sheets. Metal sheets, which act as dispensers, are designed at the height of one-third or half of the carrier metal sheets. Due to this detail in its design and production, it is defined as a half-pass grating. In this type of honeycomb grating, thanks to the use of metal sheets in the direction of the dispenser, the bending resistance of the bearing metal sheets of the grating under load is increased and the grating is made even more durable.

Among the reasons why half-pass honeycomb grating are included in the most preferred honeycomb grating models, high carrying capacity and aesthetic structure are. It is a type of grating that is light and easy to install. Half-pass gratings can be produced with different distributor and carrier options according to the project. It is often preferred in architectural projects. Ships, industrial projects, shelf and chassis systems, treatment plants, platforms and walkways are also used. The advantages of this type of grating for projects can be listed as follows:

- It has a high density and is quite light.

- It has ventilation feature.

- It is very durable and long-lasting.

- The non-slipness of the product can be increased thanks to the method of notching the metal sheets.

By the System Platform;

- Half Pass NotchEd Stair Step,

- Half Pass Notch Grating,

- Half Pass Standard Stair Step,

- Half Pass Standard Grating

Models are designed and manufactured at an affordable price, high quality and standards and in accordance with every project.

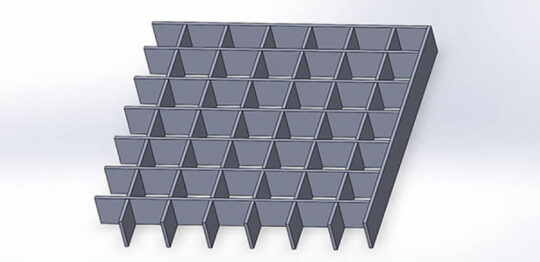

3- Full Pass Grating

The most prominent feature of full passing honeycomb gratings is their aesthetic appearance. With this feature, it is preferred in architectural areas. In addition, it is a type of grating that has the ability to move in 4 directions. Since it is usable in both directions, it is easy to assemble and has a high carrying capacity. The full passing grating system offers a rather aesthetic appearance in façade applications.

Railings are used for decorative purposes as façade dressings, ceiling decoration, sun breakers. In addition, it is often preferred in walking paths and architectural projects in areas with versatile loads.

The advantages and reasons for preference of this type of grating for projects can be listed as follows:

- It has high carrying capacity, it provides effective solutions for heavy loads.

- With low weight, it allows you to carry heavy loads.

- Project-specific production can be made in desired sizes and sizes.

- Easy to assemble.

- In the applied area, it provides a decorative appearance with its aesthetic stance.

By the System Platform;

- Full Passing Notched Stair Step,

- Full Pass Notch Grating,

- Full Pass Standard Stair Step,

- Full Pass Standard Grating.

Models are designed and manufactured at an affordable price, high quality and standards and in accordance with every project.

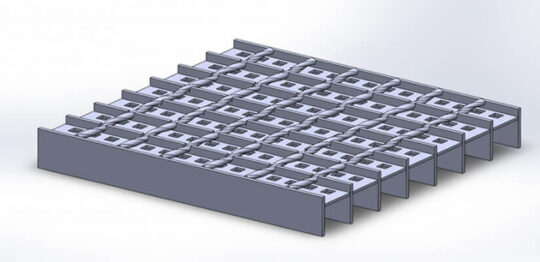

4- Custom Production Grating

Apart from existing products in the sector, productions are made in accordance with the wishes and expectations of our customers and special and flexible solutions are offered for projects.

It is among our custom production products; apart from the models of

- Perforated Sheet Metal Grating,

- Cut Grating,

- Thick Grating,

- Shelf Grating,

- Kickplated and Nostrilled Grating,

the products needed are also designed and manufactured.

The more complex and innovative the building and construction systems, the more personalized and specialized they must be. Platform grating types with a wide range of uses are specially designed and produced by System Platform, which is in the sector with more than 25 years of experience, taking into account the needs of the structure, space, facility or machine, our customers’ wishes and expectations. You can review our products of reasonable price and high quality for the honeycomb grating products you need and contact us at any time.